Mastec Components

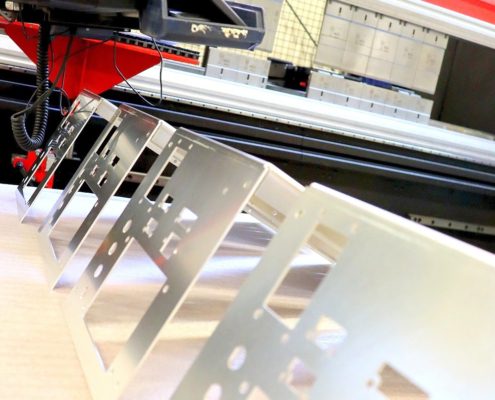

Mastec Components offers sheet metal processing by using laser cutting, bending and processing in combination with welding and assembly. This passion of ours is deeply rooted. Did you know that we have more than 120 years of experience in this field? We have a deep understanding of how to best use materials such as aluminium, stainless steel and black steel. Our costumers are reputable companies with high expectations on quality, delivery reliability, traceability, documentation, cost-efficiency and new technology – and we deliver! Try us and you’ll see!