Mastec CCTech

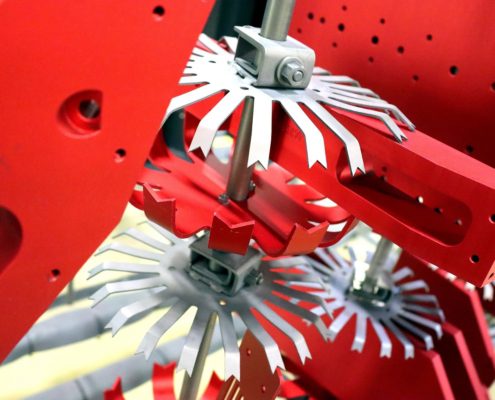

CCTech in Ulricehamn is a site where we specialize in subcontracting small to medium batches of surface treatment. In this location we have one of the industries most modern and high-tech facilities. This automated and efficient site is equipped for meeting the challenges of tomorrow and gives us the possibility of delivierng in just 5 days! The keys to success lies within continuous inspecions, meticulous process documentation and high quality. CCTech also offers surface treatments on aluminium through anodizing, passivation and chromating. You have to choice to add trumbling or assembly – we can deliver directly to the end costumer! If your time is limited it might feel good to know that we historically have been able to solve our customers needs in just 3 hours!