Mastec WTech

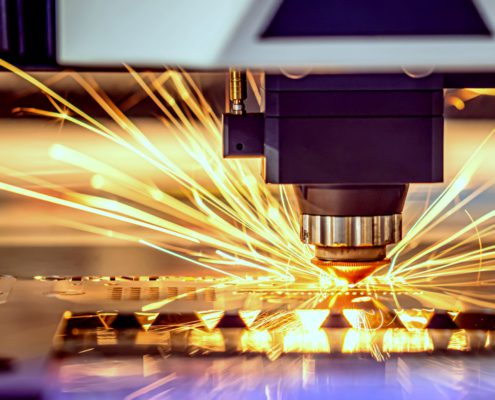

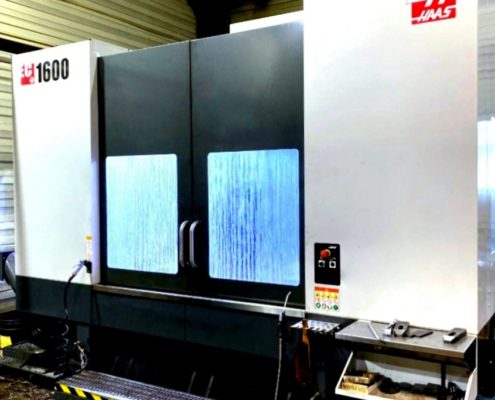

Mastec WTech was founded as early as 1991 and have developed their skills in advanced welding and machining over the last 30 years! This well-established and cost-effective site located in southern Poland became a part of Mastec in 2015. We specialize in large welded and machined structures as well as parts and modules. Our commited staff have long experience of working with sheet metal design such as canopies, enclosures, hoods and covers. For many years they have also helpt customers with hydraulic system’s steelwork and equipment such as reservoirs, frames and stands. We are an observant partner with high attention to detail! Vertical integration enables us to ensure the highest quality possible! The site is certified according to ISO 9001 and ISO 3834-2. In addition, there are also several welding certificates. Shortly – we are a reliable partner for you to work with!