Mastec Precision

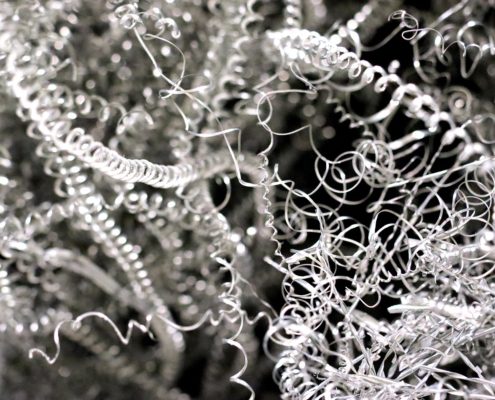

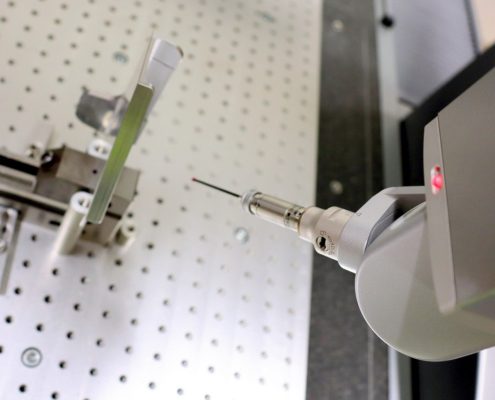

We offer advanced machining in Ulricehamn for costumers with high standards. Our machinery is up-to-date and have the capacity to produce complex structures with very high precision! We manufacture compoments in metal and plastic with high demands on tolerances, precision and surface finish. As our costumers often work within defense or medical technology we are used to meet their high expectations on quality, documentation and traceability. Did you know that we also offer complete solutions including assembling?